A vertical turbine pump is typically classified as a centrifugal or rotodynamic pump. It is a highly versatile tool used in a wide variety of industrial applications. Vertical pumps can be configured to supply both high flow and high-pressure fluid outputs. These are typically multistage devices with multiple impellers embedded in the configuration. While vertical pumps are usually used in underground operations, they have some above-ground applications as well. Here is an overview of the pump, how it works, and the most common applications.

What Is a Vertical Turbine Pump?

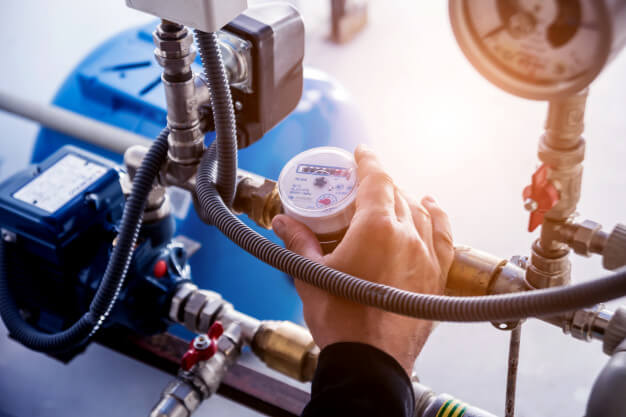

A vertical turbine pump is designed to move fluid from an underground reservoir, pit, or well to a spot above ground. Unlike other pumps, these vertical pumps are linked to a surface device through a long shaft device. Pumps are comprised of a head, motor, multiple stages, and columns to contain the shaft. The pump’s engine can be housed on the surface, making device repair more straightforward and convenient.

What Are Common Vertical Pump Applications?

A vertical turbine pump is used in various industrial, construction, and agricultural applications. These pumps are commonly used in applications that require clean water, typically industrial pump services. Turbine pumps transport water from underground wells to residential home faucets, water treatment plants, and sprinkling systems. The water transported generally is too far down to be procured without the assistance of a long shaft.

A distinct advantage of a vertical pump is its adaptability. Vertical pumps are routinely used instead of submersible pumps because they can produce a more robust water flow output. High-pressure versions can produce up to 30,000 gallons of water per minute. Low-pressure adaptations typically generate 100 gallons of fluid per minute. These pumps can be constructed with various stages, producing the pressure needed for an individual application.

Unlike many other types of pumps, the motor can be housed on the surface. Non-electrical motors can be used to produce the pump’s rotational power. Therefore, vertical pumps are a good option for a construction site without ready access to an electrical power source.

Are There Irrigation Applications for Vertical Turbine Pumps?

Irrigation applications for vertical pumps are becoming increasingly common. Many municipalities require groundwater to provide water to local homes, farms, and businesses. Vertical pumps can supply liquid to agricultural fields or homes for watering purposes. One pump is sufficient for numerous acres as it can provide water at an incredibly high volume.

Vertical pumps can also act as a booster for other pumps when outputs need to be increased for a specific project. City water systems may use a turbine pump to supplement the existing water distribution system.

What Are Other Vertical Turbine Pump Applications?

An uncommon but convenient application for a vertical pump is running it in reverse to generate hydraulic power. When used to generate power, the suction housing acts as the pump’s outlet, and the discharge housing serves as the pump’s inlet. While it can be convenient to use a vertical turbine pump to generate power, operators should check with the manufacturer before to ensure there are no safety issues.

What Are the Advantages and Disadvantages?

There are several advantages to using vertical pumps. While some industrial pumps use a large amount of energy, vertical turbine pumps have a small carbon footprint because there are generally no priming issues. The impellers are constantly covered in fluid, providing adequate moisture to the device. Furthermore, these pumps are versatile, easily customizable, and can effectively be used in high and low-flow applications.

Another distinct advantage is that vertical pumps can be housed in tight spaces, making them an ideal device for use in environments with size restrictions. Further, most pump base materials can be upgraded or improved with minimal effort and expense. Pumps can be repaired quickly and inexpensively, maximizing the pump’s life and decreasing the cost your business incurs replacing outdated equipment.

One disadvantage is the fact that these pumps require a lot of headroom for installation and repairs. Additionally, it can be challenging to balance the pump’s hydraulic thrust because of its overhang design. This design feature can be a particular challenge in high-pressure or high-stress industrial applications.

Work With an Expert

Vertical pumps are versatile devices that can be used to pump high volumes of fluid for a wide variety of applications. Zone Industries designs, installs and maintains motors, pumps, and controls. We specialize in industrial pump services and vertical turbine pump repair and installation. Don’t wait any longer to find the ideal pump supplier for your industrial or agricultural needs. Contact us today to find the perfect vertical pump to grow your business.

What Are the Main Uses for a Vertical Turbine Pump? | Zone Industries

There are many advantages to using a submersible vertical turbine pump in manufacturing, construction, and industrial applications. Besides submersible, turbine pumps come in deep well, canned, and wet pit configurations. A vertical pump is highly functional, but they need to be maintained to keep them functioning at an optimal level. Here are a few things to consider when facing repairs and maintenance issues.

Submersible Vertical Turbine Pump Overview

Unlike other models, submersible pumps are designed to work while immersed in water. These pumps are usually positioned underneath the ground to excavate water and bring it to the surface for various uses. Most turbine pumps have a shrouded impeller and receive the water at the device’s center. Diffusion rings direct the discharge along with the series of impellers. The diffusion ring alters the impeller discharge into the pressure head. All of these components work together to process the water and bring it to the surface.

Submersible Vertical Turbine Pump Maintenance

A submersible vertical turbine pump is manufactured to handle a great deal of pressure, but it must be maintained regularly to perform effectively. A proper maintenance inspection should include routine maintenance, routine examinations, three-month inspections, and annual inspections. You can shorten the amount of time between assessments if the pump is not performing optimally, the pump fluid is corrosive, or you are operating in a high-stress environment.

During routine maintenance checks, you should assess the mechanical seal and the packing seal for any tears or imperfections. You should also check the oil in the pump bearings to make sure it is not dried out. There are several tasks you should perform during routine maintenance checks to ensure the device is functioning correctly:

- Assess the oil level through the inspection window on the bearing frame

• Check for unusual sounds

• Check all pump components for leaks

• Examine the vibration

You should perform more extensive maintenance checks every three months. During these checks, examine the pump’s foundation to ensure the hold-down bolts are correctly fitted. Also, check the pump’s casing and packing, particularly if the device has been left idle for a few days. Change the oil filter every three months or more frequently if the device is used daily.

Annual Vertical Turbine Pump Inspections

You need to perform a more extensive inspection of your vertical turbine pump on an annual basis. During these yearly maintenance checks, you need to inspect the pump’s capacity, pressure, and power. You may need to perform these more thorough checks every six months if the device works in conditions that may contaminate any part of the pump.

If you are not satisfied with the pump’s performance during the yearly inspection, you should completely disassemble the device to examine each component’s functionality. You may need to replace damaged parts.

Common Submersible Vertical Turbine Pump Repairs

Several repairs are common for a vertical pump, especially ones that operate in high-stress industries. You will likely need to complete the following maintenance tasks every few years:

- Replace line shaft bearings

• Replace damaged shafting

• Clean submerged components to remove corrosion

• Apply corrosion-resistant coatings to all device surfaces

• Repair damaged impellers

Corrosion is often the primary concern when it comes to vertical turbine pump maintenance. The components submerged in water should be removed as usually as possible to apply a corrosion-resistant coating. If the device is not maintained to prevent corrosion, a total overhaul may be necessary after only a few years. Making frequent repairs can be very expensive, taking money away from your business.

Primary Vertical Pump Repair Concerns

Although a vertical turbine pump performs high-stress tasks, they are not technically sophisticated. Pumps are designed to withstand high-pressure situations, and pump mechanics must be maintained to ensure optimum performance. The primary repair concerns include:

- Dimensional reliability of device components

• Shafting straightness and dependability

• Clearance level for bowl and column bearings

• Impeller balancing

• Corrosion resistance of device coating

To address any of these concerns, most vertical pumps can be disassembled and reassembled relatively easily. It is not necessary to relocate the pump to perform repairs. Because pumps are large and cumbersome, it is best to perform maintenance checks and repairs at the location site.

Work With Zone Industries

If your submersible vertical turbine pump is not performing optimally, you need to get it repaired right away. Business owners that operate in the construction industry understand that work comes to a standstill when tools malfunction. Don’t wait any longer; get your business up and running. Zone Industries has the technical expertise to repair a vertical turbine pump quickly and efficiently. We can repair individual components or complete a total device overhaul. Contact us today to get your pumps functioning at an optimal level.

How Do You Maintain a Submersible Vertical Turbine Pump? | Zone Industries